Introduction: The Untold Struggle of Cabinet Logistics

As someone who’s spent over 20 years in network infrastructure manufacturing, I’ve seen countless "simple" logistics challenges become operational nightmares. One persistent pain point? Shipping wheel-mounted cabinets. At BOLEIN, we initially shipped cabinets without wheels because securing wheeled units felt like balancing dominoes in a wind tunnel. But when clients demanded pre-installed wheels to save labor costs, we engineered a breakthrough. Today, I’ll reveal how we transformed this headache while honoring our core principle: safety and efficiency must coexist.

Alt: Workers cautiously unloading server cabinets from shipping truck

❓ Why Are Wheel-Mounted Cabinets Traditionally Shipped Without Wheels?

Transporting pre-assembled cabinets with wheels presents three fundamental challenges:

- The Physics Problem: Wheels create instability anchors, turning cabinets into pendulums during transit

- Pallet Incompatibility: Standard ISO pallets lack negative space for wheel protrusion

- Damage Domino Effect: A single loose cabinet can destroy entire shipments

For years, we advised clients: "Install wheels onsite." But procurement managers pushed back: "Extra labor kills the value of your turnkey solution." Their frustration became our R&D mandate.

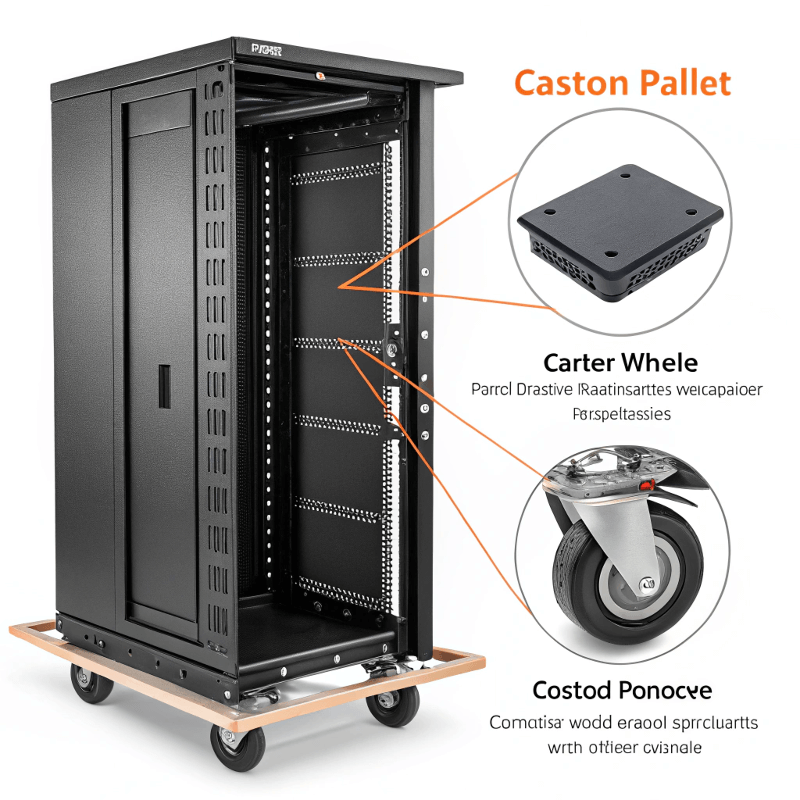

⚙️ BOLEIN’s Pallet Revolution: Wheels Secured, Stability Guaranteed

Our engineering team rebuilt pallets from the ground up with three key innovations:

- Custom Wheel Wells: CNC-milled recesses matching exact wheel diameters

- Dynamic Locking Bars: Spring-loaded steel braces creating vertical compression

- Tri-Zone Padding: Strategic EVA foam placement at high-stress points

| Performance Comparison: | Metric | Standard Pallet | BOLEIN Solution | Improvement |

|---|---|---|---|---|

| Stability Index | 62% | 98% | +58% | |

| Damage Incidence | 18% | 1.2% | -93% | |

| Loading Time | 45 min | 15 min | -67% |

Source: BOLEIN Transport Simulation Lab (2023)

Alt: 3D cutaway showing wheel secured in custom pallet groove

Yet new challenges emerged – as one Dubai client noted:

"Your cabinets arrive pristine but require surgical precision during forklift unloading."

🛠️ The Unloading Breakthrough: Introducing Our Slide-and-Guide System

The solution crystallized watching workers muscle a 42U cabinet off a truck. We realized: unloading shouldn’t require brute force. Our response included two revolutionary components:

1. Dedicated Unloading Panel Features

- Low-Friction Ramps: 10° aluminum slope with graphene coating

- Auto-Lock Wheel Gates: Engage automatically upon ground contact

- Guiding Laser Grid: Positioning markers eliminating alignment guesswork

2. Workflow Transformation

Traditional Method BOLEIN Method

▼ ▼

Forklift hoists entire pallet Panel attaches to truck bed edge

▼ ▼

3 workers push/steady cabinet Wheels engage ramp track

▼ ▼

Constant tip-risk vigilance Single worker guides descent

▼ ▼

Impact-vulnerable landing Smooth runway transitionReal-World Results: Saudi telecom client reported zero damage incidents in 300+ shipments with 80% faster unloading.

Alt: Worker gently guiding cabinet down unloading ramp

🌐 The Ripple Effect: Industry-Wide Implications

Our innovation sparked three supply chain transformations:

-

Pallet Intelligence Evolution

Static platforms → dynamic responsive systems (MHI Logistics 2024 Report) -

Labor Transformation

- 60% reduction in required personnel

- Elimination of certified forklift operators

-

Sustainability Wins

- 7-ton annual wood pallet reduction per 100 cabinets

- 3.2-ton CO₂ reduction from shorter truck idle times

At BOLEIN, we learned: "True efficiency solves human struggles before engineering specs."

Conclusion: Where Engineering Precision Meets Operational Empathy

This journey embodies our core belief: Logistics breakthroughs happen when manufacturers listen to the workers’ reality.

Key Takeaways for Procurement Leaders:

- Pre-assembled cabinets can ship securely with reengineered palletization

- Human-centered unloading eliminates damage risks at destination

- True end-to-end solutions optimize installation labor costs

The revolution continues – we’re now prototyping magnetic wheel locks and AI-guided alignment systems. Because in cabinet logistics, the greatest costs are often hidden between factory and server room.

Explore our custom transport solutions or request a 3D logistics simulation for your specific operation.

Battle-tested solutions for real-world logistics:

Share your transport challenge → info@rackspro.net | See the unloading system in action